If aerial survey drones get restricted in the U.S., you won’t just see a headline and shrug. You’ll feel it in your project schedule, your survey quote, and the files your engineer needs. Right now, a lot of survey teams rely on DJI gear because it works, crews know it, and the workflow runs fast. However, recent reporting has pointed to a “trap door” style deadline and a possible restriction path that could disrupt how easily companies can buy, replace, or support certain DJI platforms. So even if you don’t care about drone brands, you should care about what happens next.

Why this matters to real projects in Indianapolis

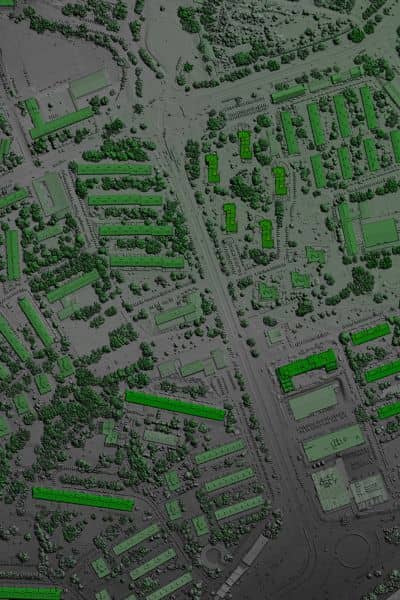

Indy stays busy. Contractors push schedules. Developers want faster decisions. Homeowners want fences, additions, and grading work done before the next season hits. Because of that, surveyors use drones to move faster on certain tasks. They capture images for site context, build mapping layers for design, and document progress during construction.

So when a big chunk of the industry relies on one drone ecosystem, any disruption hits the calendar first. Then it hits the budget. After that, it hits the deliverables—because teams sometimes change tools midstream.

What “restricted” actually means

Most clients hear “restriction” and think “no drones at all.” That’s not how it usually plays out.

Instead, a restriction often creates friction:

- A survey firm struggles to buy new units fast.

- A crew can’t replace a damaged drone quickly.

- Repairs, parts, or software access become uncertain.

- Some organizations tighten purchasing rules, which slows approvals.

In other words, the work still happens. However, the easy path disappears. Then everyone spends more time finding a new path.

Cost: where the price can move (and why)

Drone work can save time when it fits the job. Still, you pay for more than the flight. You pay for trained people, planning, field control, data processing, and quality checks. When restrictions shake the equipment side, costs can rise for a few reasons.

First, survey firms may need to change platforms. Crews must learn new controls, new apps, and new processing steps. That learning curve costs money because it takes time away from production work.

Next, firms may need new accessories and sensors. Batteries, chargers, controllers, and even cases add up. Also, if the old setup used one simple workflow, the new setup might require more steps. More steps often mean more labor.

Then you get the “queue effect.” When fewer drone crews can operate at full speed, projects stack up. As a result, some firms charge more for rush scheduling. Even if you don’t request a rush, the market can push prices upward.

Finally, rework can creep in. If your engineer expects one type of file and the survey firm switches tools, the team may need extra office time to match your standards. That doesn’t sound dramatic, yet it adds cost.

Timeline: what delays first

In construction, everyone asks the same question: “When can you deliver?” Drone disruption can affect both the flight date and the final delivery date.

The first delay often shows up before anyone flies. Survey teams still need to plan the mission, check airspace rules, confirm site access, and schedule staff. If equipment becomes harder to source, the team might reshuffle jobs based on what gear they can run that week.

The second delay can hit after the flight. Survey teams don’t just hand you photos. They process imagery, align it to ground control, and check accuracy. If the team changes software or workflows, the processing time can stretch. Also, many firms run a limited number of high-power processing stations. When more jobs pile up, that queue grows.

The third delay comes from downtime risk. A drone crash happens. A battery fails. A controller breaks. In a normal world, the firm replaces the part and moves on. In a restricted world, the firm may wait longer. That wait can push your field day back, which pushes your design start date back, which pushes your permit submittal back. And yes, the domino effect feels real in a city with tight schedules.

Deliverables: what you might receive differently

This part surprises clients the most. Many people assume drone work always produces the same outputs. In reality, the deliverable depends on the workflow.

Here are the most common deliverables connected to aerial survey drones.

Orthomosaic map (a clean overhead image). This looks like a sharp, stitched “map photo” of your site. Engineers and owners use it for context and planning. You might still get it either way. However, the resolution, the turnaround time, and the file format can change if the firm switches tools.

Surface model and contours (the “shape of the ground”). Designers use this for grading, drainage, and site layout. A good survey team checks it against ground measurements. If workflows shift, the firm may lean more on ground shots to confirm key areas. That can help accuracy, yet it can also add time.

Point cloud (a dense set of measured points). Some projects use a point cloud to model terrain, stockpiles, or site features. Different tools can output point clouds in different ways. So you may see changes in density, noise levels, or how clean the final file looks.

LiDAR outputs (when crews use LiDAR). LiDAR helps in trees and brush because it can “see” through gaps better than standard photos. Not every drone setup supports it the same way. If restrictions limit certain platforms, LiDAR work may shift to different systems. That can change price and schedule more than basic mapping.

Construction progress documentation. Owners love weekly or monthly aerial visuals. This work feels simple, yet it still relies on a consistent drone and camera setup. If a firm changes systems mid-project, your photos may not match the previous angles and color styles. That mismatch can confuse reports, especially for lenders and stakeholders.

The honest truth: survey standards don’t change, but workflows do

Restrictions don’t erase professional responsibility. A good surveyor still needs accurate control, clear scope, and defensible results. So the “quality bar” stays the same.

However, the path to hit that bar can change. Therefore, you should plan for workflow flexibility, especially if your project depends on repeat drone flights or tight design deadlines.

How you protect your project without turning it into a headache

You don’t need to become a drone expert. You just need to set expectations clearly.

Start by asking your survey firm how drone data fits your scope. If the drone work supports a topo survey, ask what other methods they can use if they can’t fly that week. Then ask what deliverables your engineer needs so the survey team can match formats from day one.

Also, ask about backup capacity. A serious firm plans for equipment failures and staffing gaps. When the market gets uncertain, that backup plan matters more.

If flood risk touches your project, you can also check the FEMA Map Service Center for your property’s flood map information. That won’t replace a survey, but it helps you understand the bigger picture before you commit to design decisions.

Final takeaway

If aerial survey drones get restricted, you won’t lose access to surveying. Instead, you may see higher costs, longer timelines, and deliverables that shift slightly as firms adapt. That matters in Indianapolis because schedules move fast and delays stack up quickly.

So if you plan a project soon—site design, grading, construction progress, or pre-development mapping—talk to your surveyor early. Lock the scope. Confirm the deliverables. Then you’ll avoid surprises even if drone supply and compliance rules change overnight.